Have you ever wondered what makes shipping containers so durable and capable of withstanding the rigors of international transport? The secret lies in their construction, particularly the materials used for their walls.

Shipping container wall construction is a critical aspect of their overall durability and functionality. The walls are not just simple partitions; they play a significant role in the structural integrity of the container.

The importance of load bearing walls in shipping containers cannot be overstated. They are designed to withstand heavy loads and stresses during transportation. For more information on the materials used in shipping containers, you can visit Universal Containers.

Key Takeaways

- The walls of shipping containers are crucial for their structural integrity.

- Shipping container walls are designed to be load-bearing.

- The materials used for the walls contribute significantly to the container’s durability.

- Understanding the construction of shipping containers can provide insights into their functionality.

- The use of appropriate materials is key to the longevity of shipping containers.

Understanding Shipping Container Construction

Understanding the construction of shipping containers is essential for appreciating their durability and versatility.

Shipping containers are built with a focus on strength and durability. The basic structure includes a steel framework that provides the primary support.

Basic Structure of a Shipping Container

The basic structure of a shipping container is composed of several key elements:

- Steel framework

- Corrugated steel walls

- Steel floor

- Wooden flooring overlay

These components work together to provide a robust and secure environment for cargo.

Standard Dimensions and Types

Shipping containers come in various sizes, with standard dimensions being 20 feet or 40 feet in length, 8 feet in width, and 8.5 feet in height.

The most common types include:

- General Purpose Containers

- High Cube Containers

- Flat Rack Containers

Each type is designed for specific cargo needs, offering flexibility in shipping options.

Materials Used in Shipping Container Construction

Understanding the materials used in shipping container construction is crucial for assessing their structural integrity and load-bearing capacity. Shipping containers are built to withstand harsh marine environments and heavy loads, making the choice of materials critical.

Steel Framework and Exterior

The primary structure of a shipping container is made from corten steel, known for its high strength and resistance to corrosion. The steel framework includes the corner posts, side rails, and cross members, which provide the container’s overall strength and stability. The exterior walls are also made of steel, often corrugated to increase their strength and resistance to deformation.

As

“The use of corten steel in shipping containers has become an industry standard due to its durability and low maintenance requirements.”

This material choice significantly contributes to the containers’ ability to withstand various environmental conditions.

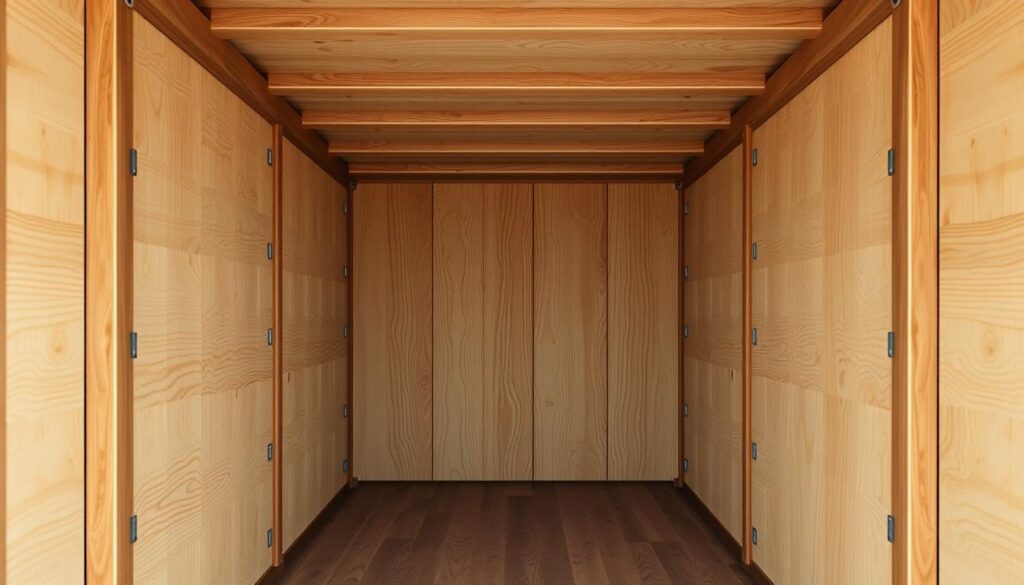

Interior Wall Materials

The interior walls of shipping containers are typically made from materials like plywood or steel. Plywood is commonly used for the interior lining due to its durability and resistance to wear. It is often treated with chemicals to enhance its resistance to pests and decay. The choice of interior material can affect the container’s overall weight and its suitability for different types of cargo.

For example, plywood lining is a popular choice because it is relatively lightweight and easy to install. However, the specific requirements of the cargo being transported can dictate the use of other materials.

The Wood Used in Shipping Containers

The use of wood in shipping containers is a common practice, serving multiple purposes. While the exterior of shipping containers is typically made of steel, the interior often incorporates wood for flooring and sometimes for other components.

Types of Wood Commonly Used

Shipping containers often utilize plywood or hardwood for their flooring due to their durability and resistance to wear. Plywood is a popular choice because it is cost-effective and provides sufficient strength. On the other hand, hardwood is valued for its density and longevity, making it suitable for heavy-duty applications.

Plywood vs. Hardwood Flooring Options

When it comes to flooring, both plywood and hardwood have their advantages. Plywood is generally more affordable and still offers good performance, whereas hardwood provides superior durability and can withstand heavier loads. The choice between the two often depends on the intended use of the shipping container and the type of goods it will transport.

Treatment and Durability of Container Wood

The wood used in shipping containers is often treated to enhance its durability and resistance to pests and decay. Treatment processes can include chemical treatments or heat treatment to ensure the wood meets international shipping standards. Proper treatment significantly extends the lifespan of the wood, making it more resistant to the rigors of shipping and storage.

Are Shipping Container Walls Load Bearing?

Understanding the load-bearing capabilities of shipping container walls is essential for safe modifications and usage. Shipping containers are designed to withstand various stresses during transportation, but their structural integrity is crucial when repurposed for housing or storage.

Definition of Load-Bearing Structures

Load-bearing structures are those that support the weight of a building or object, distributing the load to the foundation. In shipping containers, the walls, floor, and roof work together to provide structural integrity.

Load Distribution in Shipping Containers

The load in shipping containers is distributed across the structure, with the walls playing a significant role. The corrugated steel walls provide strength and help in distributing the load to the floor and roof.

Primary Load-Bearing Components

The primary load-bearing components in shipping containers include the corner castings, the floor, and the walls. These components work together to ensure the container can withstand various loads during transportation and storage.

Structural Integrity of Shipping Container Walls

Understanding the structural integrity of shipping container walls is essential for assessing their suitability for various applications.

The walls of shipping containers are critical to their overall strength and durability, designed to withstand the rigors of transportation and storage.

Wall Construction and Design

The construction and design of shipping container walls involve a combination of materials and engineering principles to achieve the required structural integrity.

Typically, the walls are made from corrugated steel, which provides excellent strength-to-weight ratio, and are designed to resist deformation under various loads.

- Corrugated steel walls offer superior strength and durability.

- The design ensures resistance to external forces such as wind and impact.

- Proper welding and assembly techniques are crucial for maintaining structural integrity.

Strength Testing and Standards

Shipping containers are subject to rigorous testing and must comply with international standards to ensure their structural integrity.

Organizations such as the International Organization for Standardization (ISO) set forth guidelines that dictate the minimum requirements for container construction, including wall strength and durability.

- Stacking tests to evaluate the container’s ability to withstand vertical loads.

- Transverse and longitudinal strength tests to assess the container’s resistance to external forces.

- Weather resistance tests to ensure the container can endure various environmental conditions.

By adhering to these standards and undergoing rigorous testing, shipping containers can ensure their structural integrity and safety for use in various applications.

How to Determine Load Bearing Walls in Shipping Containers

Determining the load-bearing walls in shipping containers is a critical step in ensuring the structural integrity of the container. This knowledge is essential for safe modifications and repurposing.

Visual Inspection Methods

A visual inspection is the first step in identifying load-bearing walls. Look for walls that are continuous from the floor to the roof and are typically made of corrugated steel. These walls are often supported by additional structural elements.

- Check for visible welds or bolts that secure the wall to the floor or roof.

- Inspect the wall’s thickness and material for signs of reinforcement.

- Look for any signs of stress or damage, such as cracks or dents.

Professional Assessment Techniques

For a more accurate assessment, consider hiring a professional to evaluate the container’s structure. They can use specialized tools and techniques to determine the load-bearing capacity of the walls.

- Professionals can conduct a detailed analysis of the container’s design and construction.

- They can identify potential weaknesses and recommend reinforcement options.

- A professional assessment can provide peace of mind for significant modifications or repurposing projects.

Load Capacity of Shipping Container Walls

Understanding the load capacity of shipping container walls is crucial for safe and effective use. The load capacity refers to the maximum weight that these walls can bear without compromising the structural integrity of the container.

Weight Limitations and Specifications

Shipping containers are designed with specific weight limitations in mind. The standard specifications for shipping containers, as outlined by organizations such as the International Organization for Standardization (ISO), dictate the maximum payload capacity. For example, a standard 20-foot shipping container typically has a maximum gross weight of around 24,000 kg (52,910 lbs), which includes the weight of the container itself, the cargo, and any additional structures or modifications. However, the load-bearing capacity of the walls specifically can vary based on the container’s design and construction.

Key specifications to consider:

- Maximum gross weight

- Payload capacity

- Wall thickness and material

As emphasized by industry experts, “The structural integrity of shipping containers is paramount, and understanding their load capacity is essential for any modification or repurposing project.”

Factors Affecting Load Capacity

Several factors can affect the load capacity of shipping container walls. These include the material used in construction, the design of the container, any modifications made, and the condition of the container. For instance, containers made from corten steel are known for their strength and durability, but even within this material category, variations in thickness and treatment can impact load capacity.

The condition of the container, including any signs of wear, rust, or damage, also plays a significant role in determining its load capacity. Regular inspections and maintenance are crucial to ensure that the container remains within safe operational limits.

“The longevity and safety of shipping container structures depend heavily on understanding and respecting their load-bearing capacities.”

By considering these factors and understanding the weight limitations and specifications, users can ensure the safe and effective use of shipping containers.

Shipping Container Wall Supports

Understanding the wall supports in shipping containers is essential for ensuring their safe use and modification. Shipping containers are designed to withstand various environmental and operational stresses, and their wall supports play a crucial role in this regard.

Built-in Support Systems

Shipping containers come equipped with built-in support systems that enhance their structural integrity. These include:

- Corrugated walls: Providing additional strength and resistance to deformation.

- Vertical and horizontal members: Such as corner posts and cross members that contribute to the overall stability of the container.

Additional Reinforcement Options

For containers that will be modified or used in demanding applications, additional reinforcement may be necessary. Options include:

- Internal bracing: Adding internal frames or braces to enhance stability.

- External reinforcement: Using external straps or plates to strengthen the container walls.

| Support System | Description | Benefits |

|---|---|---|

| Corrugated Walls | Walls with corrugated design for added strength | Resistant to deformation, enhanced durability |

| Internal Bracing | Internal frames or braces for additional stability | Improved structural integrity, enhanced safety |

| External Reinforcement | External straps or plates for wall strengthening | Increased load-bearing capacity, prolonged lifespan |

Importance of Load Bearing Walls in Shipping Containers

The role of load-bearing walls in shipping containers cannot be overstated, as they are fundamental to the structural integrity of these units. Load-bearing walls are crucial for maintaining the stability and safety of shipping containers, especially when they are modified or repurposed.

Structural Safety Considerations

From a structural safety perspective, load-bearing walls play a vital role in:

- Distributing weight evenly throughout the container

- Providing resistance against external forces such as wind and seismic activity

- Maintaining the container’s overall stability and preventing collapse

Ensuring the integrity of these walls is essential for the safe transportation of goods and for protecting people and property.

Impact on Container Repurposing

When repurposing shipping containers, understanding the importance of load-bearing walls is equally critical. Modifications that compromise these walls can significantly reduce the container’s structural integrity. For instance, cutting into load-bearing walls without proper reinforcement can lead to:

- Weakened structural stability

- Increased risk of collapse

- Potential safety hazards

Careful planning and execution are necessary to maintain the structural safety of the container during repurposing. This includes assessing the container’s condition, identifying load-bearing elements, and implementing appropriate reinforcement measures.

Modifying Shipping Container Walls

Shipping container modifications, especially wall alterations, demand a thorough understanding of the container’s structure. Modifying shipping container walls is a common practice when repurposing containers for homes, offices, or storage facilities. However, it’s crucial to approach these modifications with caution to maintain the container’s integrity.

Safe Cutting and Modification Practices

When cutting or modifying shipping container walls, it’s essential to follow safe practices. Use appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a dust mask, to protect against injuries. Utilize the right tools for the job, such as a reciprocating saw or a plasma cutter, to make clean cuts and minimize damage to the surrounding structure. It’s also vital to identify and avoid cutting through critical structural elements like the container’s corrugated metal walls, which provide significant strength.

| Modification Type | Recommended Tools | Safety Precautions |

|---|---|---|

| Cutting Walls | Reciprocating saw, Plasma cutter | PPE, Ventilation |

| Drilling | Drill press, Hand drill | Secure the container, Use correct drill bits |

Maintaining Structural Integrity During Renovations

Maintaining the structural integrity of a shipping container during renovations is paramount. When modifying walls, ensure that the changes do not compromise the container’s overall strength. This can involve reinforcing the areas around the modifications with additional steel framing or supports. It’s also crucial to assess the container’s condition before making modifications, checking for rust, damage, or wear that could affect its stability.

Wood Replacement and Maintenance in Shipping Containers

The wooden parts of shipping containers are prone to deterioration and require timely replacement and maintenance. Regular upkeep is essential to extend the lifespan of these containers and ensure they remain safe for use.

Signs of wood deterioration can be subtle, making regular inspections crucial. Some common indicators include:

- Visible cracks or splits in the wood

- Discoloration or staining

- Soft spots or areas of rot

- Increased moisture levels within the container

Signs of Deterioration

Inspecting for these signs regularly can help identify potential issues before they become major problems. For instance, a study by the International Organization for Standardization (ISO) highlights the importance of regular maintenance in prolonging the life of shipping containers.

“Regular inspection and maintenance are key to ensuring the longevity and safety of shipping containers.” –

Replacement Materials and Techniques

When replacement is necessary, choosing the right materials is crucial. Common replacement materials include treated plywood and hardwood flooring, selected based on durability and resistance to environmental factors.

| Material | Durability | Cost |

|---|---|---|

| Treated Plywood | High | Moderate |

| Hardwood Flooring | Very High | High |

Replacing wooden components requires careful consideration of the container’s design and the materials used. Techniques may vary depending on whether you’re dealing with flooring or wall linings.

By understanding the signs of wood deterioration and knowing when and how to replace wooden components, container owners can significantly extend the life of their shipping containers.

Conclusion

Shipping container construction plays a critical role in determining the load-bearing capacity of its walls. The materials used, such as steel and wood, contribute to the overall structural integrity. Understanding whether shipping container walls are load bearing is essential for safe handling, storage, and repurposing.

The importance of load-bearing walls in shipping containers cannot be overstated. These walls are fundamental to maintaining the structural safety of the container, especially when modifications are made for alternative uses. Recognizing the role of load-bearing walls helps in planning and executing safe and effective container conversions.

In conclusion, the load-bearing capacity of shipping container walls is a critical aspect of their construction and use. By understanding the materials and design that contribute to this capacity, individuals can better appreciate the importance of preserving the structural integrity of these containers, whether for shipping or repurposing.